Blog

- Home

- Blog

8 Reasons Why Mesh Wire Is Essential for Modern Industrial Applications

In today's fast-paced industrial landscape, the significance of mesh wire cannot be overstated. According to a report from MarketsandMarkets, the global wire mesh market is expected to reach USD 6.18 billion by 2025, growing at a CAGR of 3.1% from 2020. This surge is driven by the increasing demand for versatile and durable materials across various sectors, including construction, aerospace, and manufacturing.

Mesh wire's adaptability and strength make it an indispensable component in applications ranging from filtration systems to safety barriers. As industries continue to evolve, understanding the critical role that mesh wire plays in enhancing productivity and safety in modern industrial applications becomes crucial for stakeholders seeking to maintain a competitive edge.

Mesh wire's adaptability and strength make it an indispensable component in applications ranging from filtration systems to safety barriers. As industries continue to evolve, understanding the critical role that mesh wire plays in enhancing productivity and safety in modern industrial applications becomes crucial for stakeholders seeking to maintain a competitive edge.

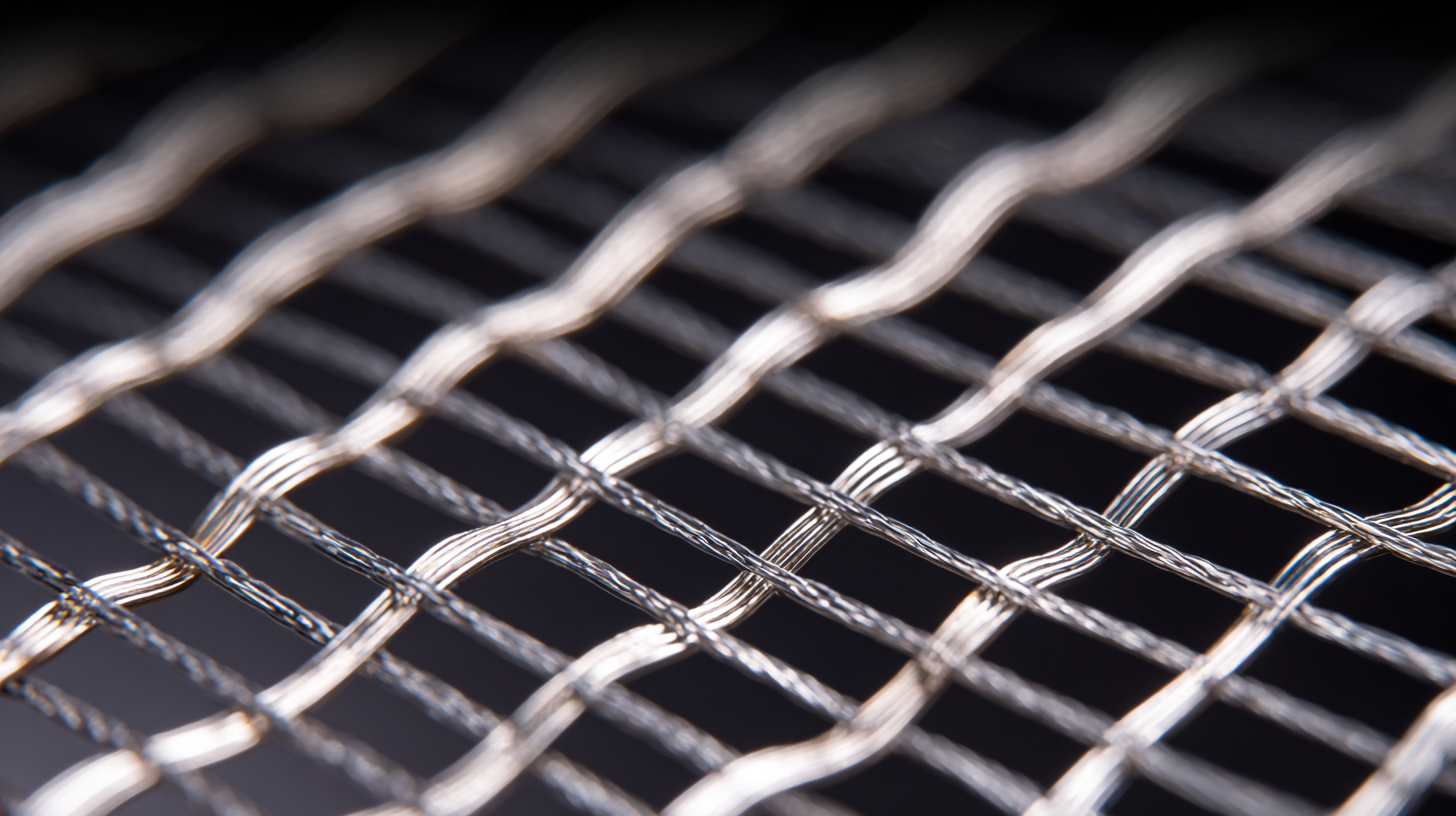

Innovative Durability: How Mesh Wire Enhances Industrial Longevity

In today’s rapidly evolving industrial landscape, the importance of innovative materials like mesh wire cannot be overstated. Mesh wire significantly enhances the longevity of various applications, particularly in construction and manufacturing. The ability of mesh wire to redistribute stress and absorb impacts makes it a crucial component in advanced construction materials such as prestressed concrete. As highlighted in recent market analyses, the prestressed concrete wire and strand sector is experiencing growth, driven by an increasing demand for durable solutions in infrastructure projects. This trend emphasizes the role of mesh wire in ensuring structural integrity and performance over time.

Furthermore, advancements in custom fabrication techniques for edge screens are revolutionizing industrial screening processes. These screens are specifically engineered to meet original equipment manufacturer (OEM) specifications, thereby enhancing productivity and efficiency across a variety of sectors. The innovative design and durability of these mesh wire products promote not only superior functionality but also a reduction in maintenance costs, ensuring a long-lasting performance that is essential in high-demand environments. As industries continue to prioritize sustainability and operational efficiency, the reliance on robust materials like mesh wire will undoubtedly remain a focal point of development.

Versatile Applications: Expanding Possibilities with Mesh Wire Solutions

Mesh wire has become a cornerstone in numerous industrial applications, thanks to its unparalleled versatility. This adaptable material can be customized to meet specific requirements across various sectors, from construction to agriculture. For instance, in construction, mesh wire provides structural integrity and reinforcement for concrete and masonry, enhancing safety and durability. Its lightweight nature also allows for easy installation and manipulation, making it a go-to choice for builders and architects alike.

In the realm of agriculture, mesh wire solutions offer innovative ways to protect crops and manage livestock. By serving as fencing or netting, it helps keep pests at bay while allowing sunlight and moisture to reach plants. Additionally, mesh wire facilitates effective drainage systems, promoting healthier soil conditions. The potential applications of mesh wire are virtually limitless, enabling industries to push boundaries and explore new possibilities in design and functionality. As businesses increasingly seek sustainable and efficient solutions, mesh wire is proving essential for modern industrial challenges.

Safety First: The Role of Mesh Wire in Industrial Risk Management

In today’s industrial landscape, safety remains a paramount concern, and mesh wire emerges as a critical component in effective risk management strategies. By providing robust barriers and clear visibility, mesh wire helps to delineate hazardous areas, ensuring workers are aware of potential dangers. This proactive approach significantly reduces the risk of accidental injuries, as it not only restricts access to dangerous zones but also maintains a secure environment for both personnel and equipment.

Moreover, mesh wire facilitates proper ventilation and visibility in operational spaces. In industries where gases and fumes pose a safety threat, mesh wire structures allow for airflow while preventing unwanted access to perilous areas. This dual functionality supports an overall safer work environment, promoting the health and safety of workers. By integrating mesh wire into their safety protocols, companies can enhance their risk management efforts, demonstrating a commitment to protecting their workforce and sustaining operational efficiency.

8 Reasons Why Mesh Wire Is Essential for Modern Industrial Applications

Cost-Effective Efficiency: Reducing Waste with Mesh Wire Deployment

In today’s manufacturing landscape, utilizing mesh wire can dramatically enhance efficiency and reduce waste. Its design allows for optimal material flow, ensuring that resources are used effectively with minimal excess. This cost-effective solution can lead to significant savings in both time and materials, making mesh wire an invaluable asset for industrial applications.

Tips for deployment include assessing the specific needs of your operations. Evaluate the type of materials being processed and the scale of the production to determine the appropriate mesh size and configuration. Additionally, consider regular maintenance schedules to ensure the mesh wire remains in optimal condition, thereby prolonging its life and performance.

Another crucial tip is to integrate mesh wire into your existing systems gradually. Start with a pilot project to understand its impact on your workflows before full-scale implementation. This approach allows for adjustments based on real-world feedback, ensuring that the deployment is truly effective and aligned with operational goals. Embracing these strategies can lead to a more streamlined process and a notable reduction in waste.

Sustainable Practices: Eco-Friendly Benefits of Using Mesh Wire in Industry

The adoption of mesh wire in modern industrial applications is not only about functionality but also about embracing sustainable practices. Recent studies illustrate that incorporating various eco-friendly wire mesh configurations can significantly enhance the sustainability of construction materials, particularly in reinforced concrete structures. This aligns with wider trends in eco-sensitive building methods that seek to reduce environmental impact while maintaining structural integrity.

For instance, data on recycled plastic pellets reveal a 42% reduction in carbon emissions when compared to traditional plastic production. This is a compelling argument for industries to consider the environmental benefits of using recycled materials, including wire mesh that integrates these eco-friendly practices. Similarly, research into natural fiber composites reinforced with wire mesh indicates promising advancements towards creating more sustainable construction materials.

Tip: When selecting wire mesh for your projects, consider options made from recycled or natural materials to minimize your environmental footprint.

Tip: Stay informed about innovations in sustainable materials, as adopting newer technologies can lead to significant cost savings and environmental benefits over time.