Blog

- Home

- Blog

Maximizing Safety and Efficiency: The Essential Guide to Choosing the Right Cable Trunking Solutions

In today's rapidly evolving electrical and construction industries, the significance of effective cable management cannot be overstated. Cable trunking, an essential component for safeguarding cables and optimizing workplace efficiency, has seen substantial growth, with the global cable management market projected to reach $36 billion by 2026, as reported by ResearchAndMarkets. Choosing the right cable trunking solutions not only enhances safety by minimizing risks associated with exposed wires but also streamlines maintenance processes, resulting in a 25% reduction in downtime, according to industry analyses. With various materials and configurations available, understanding the specific requirements of each project is crucial. This guide aims to equip professionals with the insights necessary to make informed decisions, ensuring both safety and efficiency are maximized in any installation project.

Understanding Cable Trunking: Types, Materials, and Applications

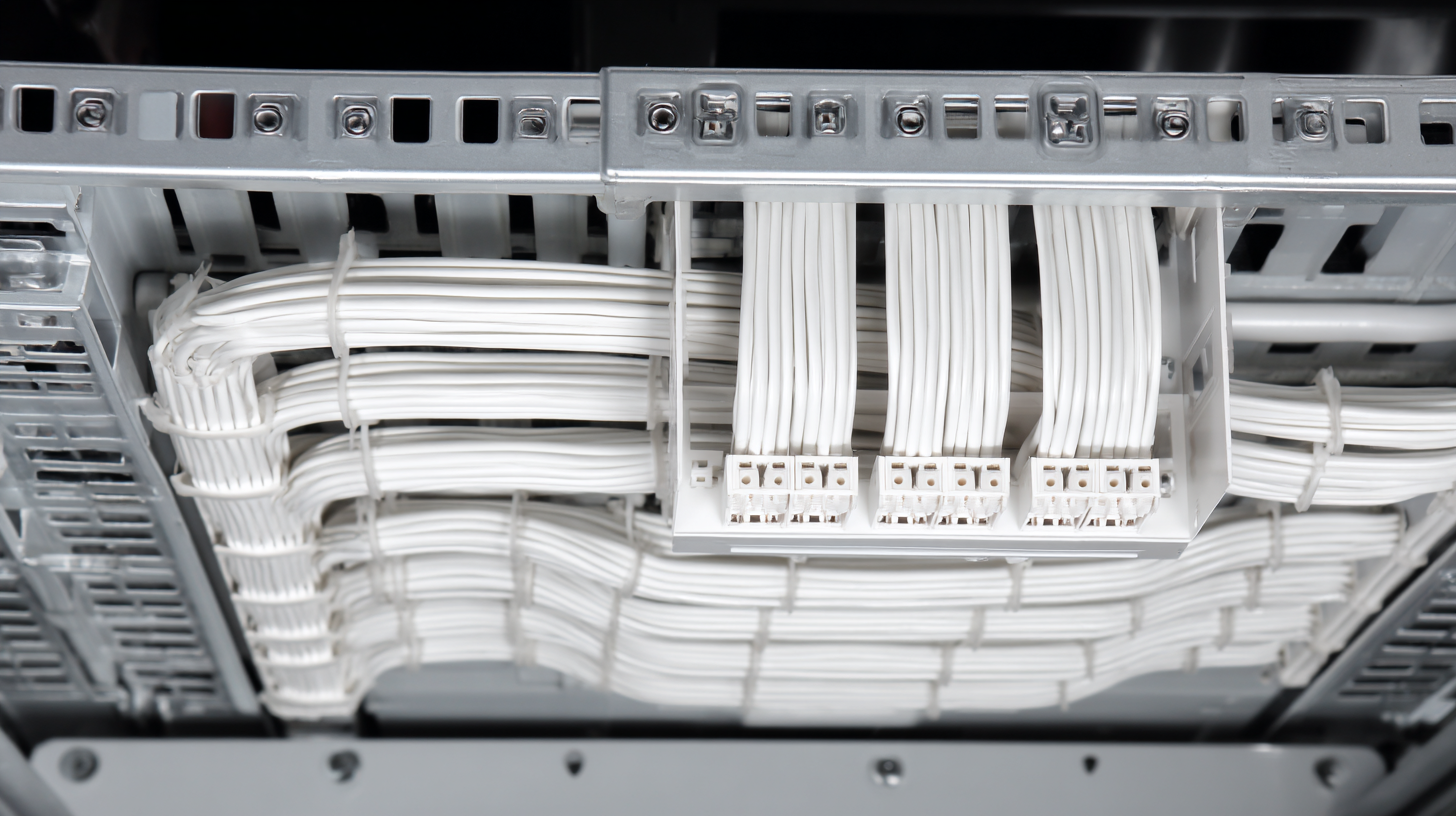

Cable trunking systems play a crucial role in efficient cable management within various environments, especially in industrial and commercial sectors. Understanding the different types and materials available is essential for selecting the right solution. The primary types of cable trunking include metal trunking, plastic trunking, and wire mesh trunking, each offering unique advantages. Metal trunking, typically made from aluminum or steel, provides robust protection and is ideal for heavy-duty applications. In contrast, plastic trunking is lightweight and resistant to corrosion, making it suitable for environments with moderate cable loads.

The choice of material significantly impacts the effectiveness and longevity of the cable trunking system. Aluminum is favored for its lightweight yet strong properties, whereas steel offers superior durability and strength, making it more suitable for heavy industrial applications. Fiber-reinforced plastics (FRP) present a versatile option that combines strength with resistance to various environmental factors. Understanding these materials, along with regular applications in construction, telecommunications, and renewable energy sectors, allows for informed decisions that maximize both safety and efficiency in cable management.

Maximizing Safety and Efficiency: The Essential Guide to Choosing the Right Cable Trunking Solutions

| Cable Trunking Type | Material | Applications | Fire Rating | Installation Method |

|---|---|---|---|---|

| PVC Trunking | Polyvinyl Chloride | Residential, Commercial | Class 1 | Clip-on |

| Metal Trunking | Steel or Aluminum | Industrial, Data Centers | Class 0 | Screw-fixed |

| Flexible Trunking | Polyurethane | HVAC, Temporary Installations | Class 1 | Bendable |

| Cable Ladder | Steel | Heavy Industrial, Power Applications | Class 0 | Mounted |

| Wire Basket Tray | Steel Wire | Data Transmission, Telecom | Class 1 | Suspended |

Key Factors to Consider When Selecting Cable Trunking Solutions

When selecting cable trunking solutions, several key factors must be taken into consideration to ensure both safety and efficiency. The growth of the global single rail cable tray market, projected to be worth $87.64 million by 2025 and reaching approximately $142.48 million by 2032, underscores the increasing demand for reliable cable management systems. This market expansion underscores the importance of choosing the right materials and designs that comply with safety regulations while also facilitating efficient cable organization and access.

In the U.S., the cable tray market size was valued at USD 818.89 million in 2022 and is forecasted to grow at a compound annual growth rate (CAGR) of 12.02% during the upcoming years. This growth highlights the need for businesses to prioritize their infrastructure choices carefully. Considerations such as the environmental conditions, load capacity, and installation accessibility can make a significant difference in both the long-term efficacy and safety of a cable trunking solution. By paying close attention to these factors, organizations can maximize their operational efficiency while minimizing safety risks.

Tips for Ensuring Safety Compliance in Cable Management

When managing cable installations in small blocks, fire safety should be a paramount concern. According to industry reports, improper cable management contributes to approximately 15% of all electrical fire incidents. To mitigate risks, it's essential to adhere to safety compliance regulations, which not only enhances safety but also boosts operational efficiency.

Tips for Ensuring Safety Compliance in cable management include ensuring that trunking solutions are made from non-combustible materials. This helps in slowing down the spread of fire and protecting the building's infrastructure. Additionally, maintain clear access to cable management systems, allowing for quick inspections and maintenance. Regularly scheduled audits can play a crucial role in identifying potential hazards before they escalate.

Another critical aspect is adhering to the relevant fire safety standards, such as BS 7671 in the UK. This standard outlines the proper installation practices that minimize fire risks. Ensuring that all cables are adequately rated for their application and are not overloaded is vital, as overloaded systems are a significant fire hazard. By prioritizing proper cable management and compliance with these guidelines, the safety and efficiency of your installations can be significantly enhanced.

Best Practices for Installing and Maintaining Cable Trunking

When it comes to ensuring a safe and efficient workspace, the proper installation and maintenance of cable trunking are paramount. Proper installation not only prevents hazards such as electrical fires and tripping, but also promotes smooth operations by managing cables neatly. Start by selecting the right trunking materials that fit your environment and cable type. Always adhere to local building codes and standards to ensure compliance and safety.

Tip: Before installation, thoroughly plan the route and layout of your trunking system. Measure accurately and mark the positions of the trunking to avoid unnecessary modifications later. Use appropriate fixings and supports to secure the trunking, ensuring it can withstand potential stresses from cables and other external factors.

Regular maintenance of your cable trunking is equally important. Inspect for signs of wear, damage, or blockages. Ensure that removable covers are clean and reattached securely to protect against dust and debris that could affect cable integrity. Additionally, consider labeling cables within the trunking to facilitate easy identification and maintenance in the future.

Tip: Schedule routine checks and create a maintenance log to keep track of inspections and repairs. This proactive approach can help prevent issues before they arise, ensuring that your cable management system remains safe and efficient.

Maximizing Safety and Efficiency: Cable Trunking Installation Analysis

Maximizing Efficiency: Organizing Your Cables for Optimal Performance

Efficient cable management plays a pivotal role in enhancing the performance and safety of electrical installations. According to a report by Allied Market Research, the global cable management market is projected to reach $51.81 billion by 2025, growing at a CAGR of 9.3%. This surge underscores the importance of selecting appropriate cable trunking solutions that not only organize cables but also prevent hazards associated with tangled or improperly secured wiring.

Cable trunking systems help in reducing electromagnetic interference (EMI), which can affect the performance of sensitive electronic equipment. A study by TechNavio highlights that employing effective cable management solutions can minimize downtime by up to 30% in industrial settings. By providing dedicated pathways for cables, trunking systems enable easier maintenance and adaptability as needs evolve, ensuring optimal performance. Properly organized cables also create a safer work environment, reducing the risk of trips and falls caused by loose wiring.

Related Posts

-

How to Choose the Right Cable Trunking for Your Electrical Installations

-

How to Choose the Right Welded Wire Mesh for Your Construction Projects

-

Challenges Faced While Sourcing Wire Mesh Panels: A Global Procurement Perspective

-

7 Best Strategies to Choose the Right Fence Netting for Your Needs

-

The Essential Guide to Understanding the Benefits of Welded Mesh in Modern Construction

-

Ultimate Guide to Wire Tray Options for Industrial Applications