Blog

- Home

- Blog

How to Choose the Right Cable Trunking for Your Electrical Installations

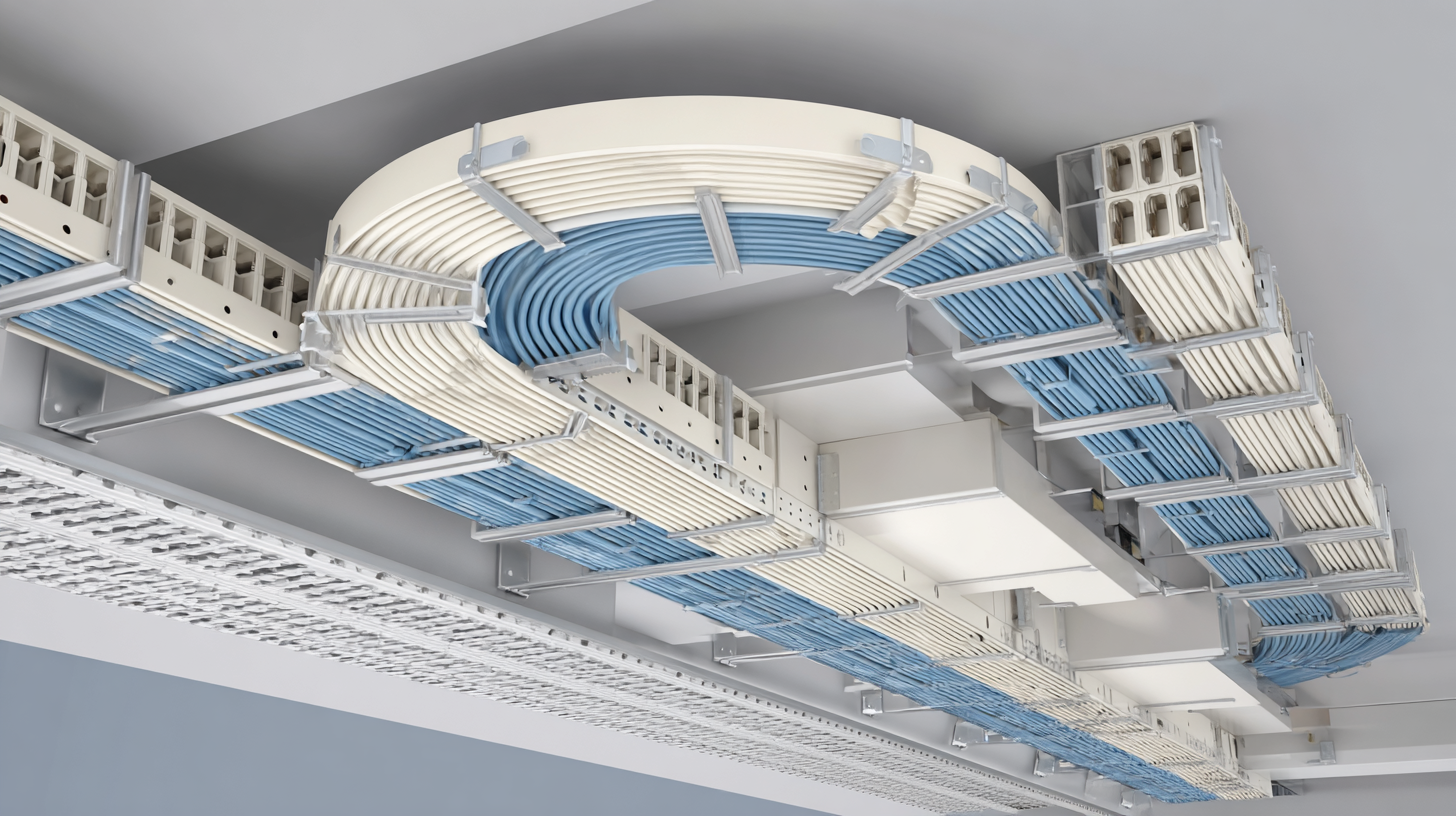

When it comes to electrical installations, one of the most critical aspects is the selection of the appropriate components to ensure safety and efficiency. Among these components, cable trunking plays a pivotal role in managing and protecting electrical wiring. Choosing the right cable trunking not only enhances the longevity of the electrical system but also contributes to maintaining an organized and aesthetically pleasing environment. With a variety of materials, sizes, and functionalities available in the market, it can be daunting to decide the best options for your specific needs. This guide will walk you through the essential factors to consider when selecting cable trunking, including environmental conditions, installation location, and compliance with electrical regulations. By understanding these criteria, you can make informed decisions that will facilitate a successful electrical installation while ensuring safety and performance.

Factors to Consider When Selecting Cable Trunking for Electrical Systems

When selecting cable trunking for electrical systems, several key factors must be considered to ensure safety, efficiency, and compliance with regulatory standards. The material of the trunking plays a critical role; options such as PVC, steel, and aluminum each offer distinct advantages and are suited for different environments. For example, PVC is lightweight and corrosion-resistant, making it ideal for indoor applications, while steel provides better strength for industrial settings where impact resistance is crucial.

When selecting cable trunking for electrical systems, several key factors must be considered to ensure safety, efficiency, and compliance with regulatory standards. The material of the trunking plays a critical role; options such as PVC, steel, and aluminum each offer distinct advantages and are suited for different environments. For example, PVC is lightweight and corrosion-resistant, making it ideal for indoor applications, while steel provides better strength for industrial settings where impact resistance is crucial.

Another important factor is the size and capacity of the trunking. It is essential to adequately assess the volume of cables intended to be housed within the trunking to avoid overcrowding, which can lead to overheating and potential hazards. Additionally, the layout of the installation area should inform the choice; straight runs may require different trunking designs compared to setups needing bends or junctions. Finally, compliance with local electrical codes and standards cannot be overlooked, as this ensures the safety and reliability of the electrical installations. These considerations collectively guide the selection of the most suitable cable trunking for specific electrical applications.

Understanding Different Types of Cable Trunking Materials and Their Applications

When it comes to electrical installations, selecting the appropriate cable trunking material is crucial for ensuring safety, performance, and longevity. Various types of materials are available, each suited to different applications. PVC is a popular choice due to its durability, corrosion resistance, and cost-effectiveness, making it ideal for indoor settings. On the other hand, metal trunking, such as aluminum or steel, offers superior strength and is often used in harsh environments where additional protection is needed.

Tips: Consider the environment where the trunking will be installed. Factors like exposure to chemicals, moisture, and temperature fluctuations can influence your choice. For instance, if you're working in a wet area, opting for metal or specially coated PVC can help prevent degradation over time.

Another key consideration is the size and capacity of the trunking. Ensuring that the chosen trunking can accommodate current and future cable sizes is essential for scalability. Always evaluate the layout and expected cable load to ensure an efficient installation. Proper planning can save time and resources in the long run, promoting a safer electrical system.

Evaluating Cable Load Capacity: Industry Standards and Best Practices

When selecting cable trunking for electrical installations, evaluating the cable load capacity is essential to ensure compliance with industry standards and best practices. The capacity of cable trunking is primarily influenced by factors such as the type of cables used, their insulation, and the configuration within the trunking. It is crucial to refer to established guidelines, such as those set by the National Electrical Code (NEC) or local regulations, which provide specifications on maximum load capacities and installation practices to avoid overheating and electrical hazards.

Moreover, understanding the environmental conditions where the trunking will be installed affects the load capacity. For instance, trunking installed in high-temperature areas may need to accommodate lower cable quantities to prevent thermal buildup. The compatibility of the materials used in the trunking with the cables is also vital; choosing materials that can withstand temperature fluctuations and chemical exposure ensures durability and safety. By assessing these factors and adhering to best practices, one can significantly enhance the reliability and efficiency of electrical installations while maintaining compliance with relevant standards.

Assessing Environmental Conditions for Optimal Cable Trunking Performance

When selecting cable trunking for electrical installations, it's crucial to assess environmental conditions to ensure optimal performance. Factors like temperature, humidity, and exposure to chemicals can significantly impact the lifespan and efficiency of your trunking solutions. For instance, installations in damp environments require moisture-resistant materials to prevent corrosion and electrical failures.

**Tips:** Always consider the specific environmental challenges your trunking will face. If you're working in an outdoor setting, choose trunking that offers UV protection. For indoor applications in high-humidity areas, opt for materials that can withstand moisture without degrading.

Moreover, assess the potential for physical impacts on the trunking. Areas with high foot traffic or machinery movements demand more robust and impact-resistant options. Implementing appropriate cable trunking not only protects electrical systems but also contributes to workplace safety.

**Tips:** Conduct a thorough risk assessment of the intended installation area. Utilize trunking that is designed for high-impact environments to safeguard your electrical lines effectively and minimize maintenance costs over time.

Environmental Conditions Impact on Cable Trunking Performance

This chart illustrates the correlation between different environmental conditions and their impact on the performance of cable trunking used in electrical installations. It highlights factors such as temperature, humidity, and exposure to chemicals which can affect the reliability and longevity of the trunking systems.

Regulatory Compliance: Ensuring Your Cable Trunking Meets Electrical Codes

When selecting cable trunking for electrical installations, regulatory compliance is paramount. Electrical codes are established to ensure safety, promote efficient installation, and minimize fire hazards. It is essential to verify that the chosen trunking materials and designs adhere to local and national regulations. This often involves consulting standards such as the National Electrical Code (NEC) in the United States or the IEC standards internationally. Ensuring that your trunking system complies with these codes not only protects installation integrity but also enhances the reliability of the overall electrical system.

Additionally, understanding the specific requirements for different environments is critical. For instance, trunking used in industrial settings may require additional protection against physical damage and exposure to chemicals, while residential installations might prioritize aesthetics alongside compliance. Before finalizing your selection, it's wise to review all relevant documentation and possibly seek advice from a qualified electrician. This proactive approach can help avoid costly mistakes and ensure that your electrical installations are safe, compliant, and functioning efficiently.

How to Choose the Right Cable Trunking for Your Electrical Installations - Regulatory Compliance: Ensuring Your Cable Trunking Meets Electrical Codes

| Dimension | Description | Recommended Materials | Compliance Standards |

|---|---|---|---|

| Size | The dimensions of the trunking should accommodate the number and size of cables. | PVC, metal | IEC 60332 |

| Material | The material impacts durability and environment suitability. | Aluminum, steel | UL 94, IEC 60670 |

| Mounting Type | Type of installation needed for the trunking. | Surface-mounted, recessed | NEC, BS 7671 |

| Capacity | The amount of cables that can be installed. | Standard size, custom size | IEEE 802.3, BS EN 50085 |

| Fire Rating | The fire resistance of the trunking. | Flame retardant materials | BS 476, ISO 1182 |

Related Posts

-

What is the Process of Installing Welded Wire Fence

-

8 Reasons Why Mesh Wire Is Essential for Modern Industrial Applications

-

How to Choose the Right Fence Wire for Your Specific Needs and Projects

-

Future Trends in Best Cable Mesh Market Analysis by 2025 with Real World Examples

-

Understanding the Unique Benefits of Cable Mesh for Your Industrial Applications

-

Evaluating the Benefits of Welded Wire Mesh Fence Against Traditional Fencing Solutions