Blog

- Home

- Blog

Top 10 Benefits of Using Wire Mesh Cable Trays for Your Electrical Needs

In the evolving landscape of electrical management, the choice of cable support systems plays a crucial role in ensuring efficiency, safety, and longevity. One solution that has gained remarkable popularity is the wire mesh cable tray. According to industry expert, John Smith, "Wire mesh cable trays combine versatility and durability, making them ideal for both commercial and industrial applications." This statement encapsulates the essence of why wire mesh cable trays are increasingly favored by electrical engineers and contractors alike.

Wire mesh cable trays provide a range of benefits, from enhanced ventilation to a reduction in cable overheating, making them an optimal choice for various environments. Their open design not only allows for easy access to cables for maintenance but also facilitates efficient heat dissipation, which is critical for performance. Moreover, the lightweight nature of wire mesh trays simplifies installation and offers a cost-effective solution for cable management.

In this article, we will explore the top ten benefits of using wire mesh cable trays for your electrical needs, shedding light on how this innovative solution can streamline operations while promoting safety and compliance in electrical installations.

Benefits of Wire Mesh Cable Trays in Electrical Installations

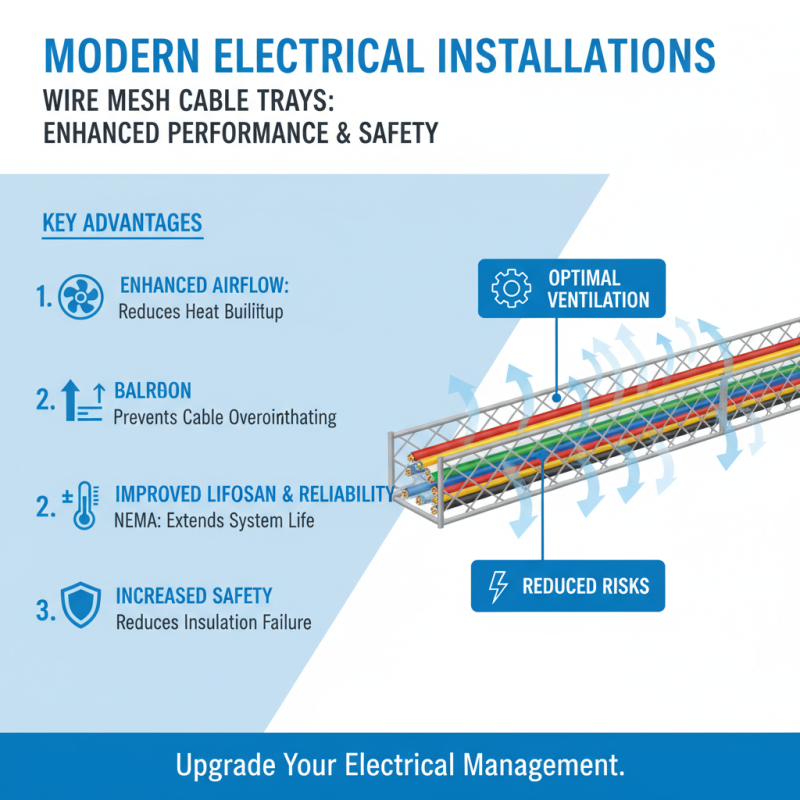

Wire mesh cable trays have become a popular choice in modern electrical installations due to their numerous advantages over traditional cable management solutions. One significant benefit is their enhanced airflow capability, which is essential for reducing heat buildup around electrical cables. According to the National Electrical Manufacturers Association (NEMA), efficient heat dissipation can improve the lifespan and performance of electrical systems. The use of wire mesh cable trays allows for optimal ventilation, which can lead to a reduction in cable insulation failure rates, ultimately enhancing the overall safety and reliability of electrical installations.

Another noteworthy advantage of wire mesh cable trays is their flexibility and ease of installation. Unlike rigid conduit systems, wire mesh trays can be easily adjusted and reconfigured to accommodate changes in cable layout or added equipment. The American National Standards Institute (ANSI) reports that flexibility in electrical infrastructure can significantly reduce installation time and labor costs, making them an economical choice for businesses. Furthermore, these trays are typically made from corrosion-resistant materials, ensuring long-term durability and minimizing maintenance, which is particularly advantageous in harsh environments. This durability not only aids in lowering replacement costs but also contributes to the sustainability of electrical installations, aligning with industry trends towards greener practices in infrastructure management.

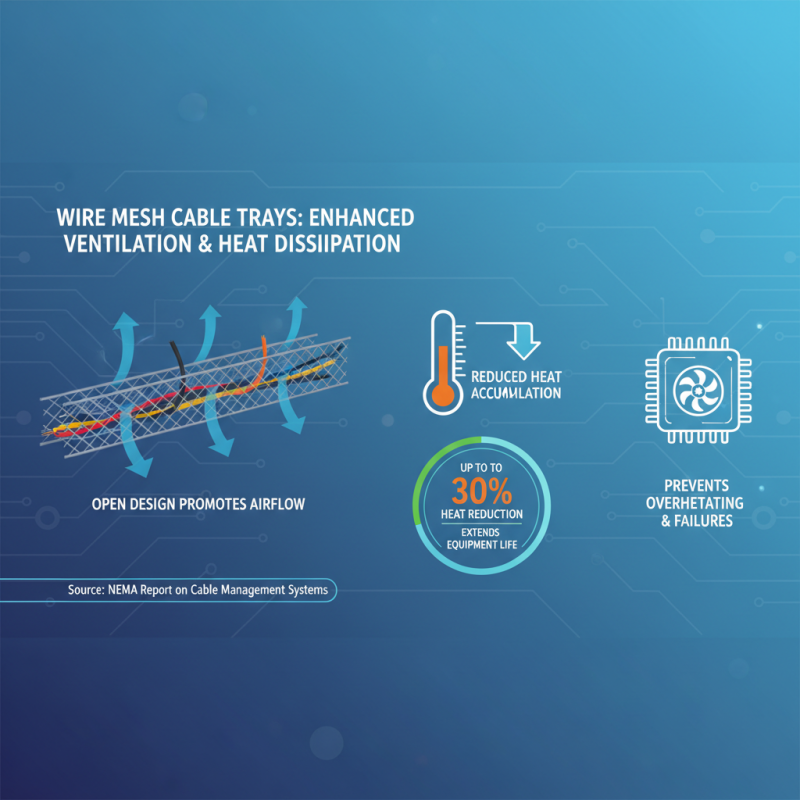

Enhanced Ventilation and Heat Dissipation in Cable Management

Wire mesh cable trays have gained popularity in electrical infrastructure due to their distinct advantages, particularly in enhancing ventilation and heat dissipation. Effective cable management is crucial in preventing overheating, which can lead to equipment failure and increased operational costs. According to a report by the National Electrical Manufacturers Association (NEMA), proper cable management systems can reduce heat accumulation by up to 30%, significantly extending the life of electrical components and systems. The open design of wire mesh trays promotes airflow around the cables, facilitating heat exchange and minimizing the risk of thermal buildup.

In addition to temperature control, the use of wire mesh cable trays offers flexibility in installation and maintenance. The ability to easily adjust the tray's configuration allows for efficient rerouting of cables, which can be critical during system expansions or upgrades. A study by the Institute of Electrical and Electronics Engineers (IEEE) emphasizes that maintaining optimal temperatures within electrical systems not only improves performance but also enhances safety by mitigating the risks associated with overheating. By integrating wire mesh cable trays into electrical layouts, organizations can achieve superior heat dissipation and ensure a more reliable and efficient power distribution system.

Improved Accessibility and Ease of Maintenance with Wire Mesh Designs

Wire mesh cable trays have become increasingly popular in various industries due to their numerous advantages, particularly when it comes to accessibility and ease of maintenance. Unlike traditional conduit systems, wire mesh designs offer an open structure that allows for superior airflow and visibility. This characteristic simplifies inspections and maintenance, making it easier for technicians to access cables without needing extensive disassembly. A notable study from the National Electrical Manufacturers Association highlights that facilities using wire mesh trays report a 30% reduction in downtime during maintenance activities, demonstrating the operational efficiency these trays provide.

Additionally, wire mesh cable trays are designed to accommodate the dynamic needs of modern electrical systems. Their versatility means that changes can be made quickly and without the need for extensive labor, which is particularly beneficial in environments where technology is rapidly evolving. According to a recent report by the Electrical Contractors Association, businesses that implement wire mesh cable trays experience up to a 25% increase in their overall maintenance efficiency, allowing them to adapt to new installations or alterations more flexibly. This increased adaptability not only enhances operational efficiency but also prolongs the lifespan of electrical installations by minimizing wear and tear.

Cost-Effectiveness and Durability of Wire Mesh Cable Trays

Wire mesh cable trays have gained popularity in electrical installations due to their

cost-effectiveness and durability. One of the primary benefits of using these cable trays is that they often come at a lower initial investment compared to other types, such as solid-bottom trays. This is mainly because the materials used in wire mesh construction are generally less expensive. Furthermore, the lightweight design of wire mesh trays facilitates easier transportation and installation, thereby reducing labor costs. The open design also allows for better air circulation, which can lead to lower overall energy costs when maintaining electrical systems.

In addition to their cost-effectiveness, wire mesh cable trays are renowned for their durability. They are typically made from galvanized steel or other robust materials, providing resistance to corrosion and wear over time. This makes them suitable for a variety of environments, including those that may be exposed to harsh conditions. The ability to withstand substantial weight while maintaining structural integrity ensures that these trays can support heavy cabling systems without the risk of sagging or damage. Overall, their combination of affordability and long-lasting performance makes wire mesh cable trays an optimal solution for managing electrical needs in both residential and commercial applications.

Versatile Applications and Adaptability for Various Electrical Systems

Wire mesh cable trays have become increasingly popular due to their versatility and adaptability for various electrical systems. These trays offer a robust yet lightweight solution for managing and protecting a wide range of electrical cables in diverse environments, from industrial facilities to commercial buildings. According to a report by MarketsandMarkets, the global cable tray market is projected to achieve significant growth, highlighting the increasing demand for efficient cable management solutions.

One of the primary advantages of wire mesh cable trays is their ability to accommodate various cable types and sizes. This adaptability makes them suitable for applications in different industries, including telecommunications, power generation, and construction. The open mesh design allows for excellent airflow, which helps in cooling electrical cables and prevents overheating, a crucial factor in maintaining system efficiency. Additionally, their modular nature facilitates easy installation and modification, allowing for future adjustments as electrical systems evolve.

Tips: When selecting wire mesh cable trays, consider factors such as load-bearing capacity and environmental exposure. Ensure that the trays meet the required standards for safety and performance in your specific application. Regular inspections and maintenance can significantly extend the lifespan of the trays, reducing long-term costs associated with cable management systems.

Top 10 Benefits of Using Wire Mesh Cable Trays

This chart illustrates the top benefits of using wire mesh cable trays in electrical systems, highlighting their versatility and adaptability across various applications.

Related Posts

-

Top 10 Benefits of Using Welded Wire Mesh for Your Projects

-

Ultimate Guide to Wire Tray Options for Industrial Applications

-

Exploring Cable Fences Innovations at the 138th Canton Fair in 2025

-

The Essential Guide to Understanding the Benefits of Welded Mesh in Modern Construction

-

Unveiling Industry Trends for Cable Racks at the 138th China Import and Export Fair 2025

-

How to Choose the Right Fence Wire for Your Specific Needs and Projects