Blog

- Home

- Blog

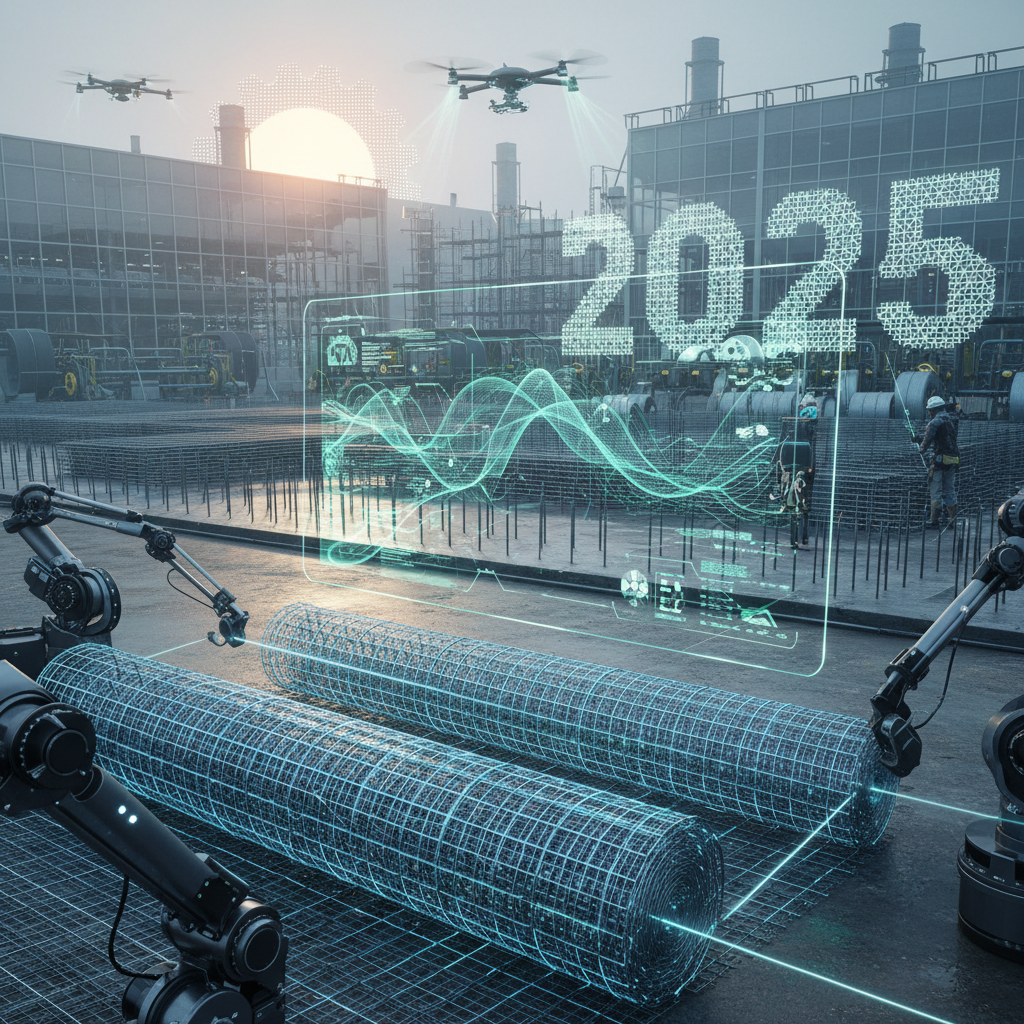

Top 2025 Welded Mesh Innovations for Construction and Industrial Applications

In the ever-evolving landscape of construction and industrial applications, welded mesh stands out as a vital component that underpins many structural and safety advancements. As we look towards 2025, innovations in welded mesh technology are poised to reshape how we approach various projects. This introduction explores the most significant innovations set to influence the use of welded mesh in the coming years, highlighting their potential to enhance efficiency, durability, and sustainability.

The integration of digital technologies is revolutionizing the manufacturing and application processes of welded mesh, enabling more precise designs and faster production times. With advancements such as automated production lines and smart monitoring systems, the welded mesh industry is not only improving product quality but also reducing waste and increasing overall project efficiencies. As these innovations take hold, they will redefine the standards of construction and industrial applications while meeting the growing demands for safety and performance.

In this exploration of the top welded mesh innovations for 2025, we will delve into the various technological advancements, new materials, and enhanced manufacturing techniques that are set to transform the industry. By focusing on the intersection of technology and practical application, this discussion aims to illustrate how welded mesh continues to be at the forefront of construction and industrial progress, paving the way for a more innovative future.

Emerging Technologies in Welded Mesh Production for Enhanced Durability

The welded mesh industry is experiencing

significant advancements as emerging technologies

revolutionize the production process, enhancing

durability and performance for construction and industrial applications.

According to a report by Smithers Pira, the global market for welded mesh

is projected to reach $4.5 billion by 2025, driven by increased demand for

sustainable and resilient building materials.

Innovations such as automated welding techniques and high-strength steel alloys are not only

improving the longevity of welded mesh products but also streamlining manufacturing

processes to reduce waste and cost.

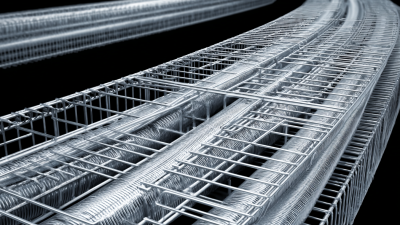

Additionally, advancements in surface treatment technologies, such as

galvanization

and polymer coatings, are enhancing corrosion resistance, making welded mesh suitable for

harsh environmental conditions. A study by Research and Markets indicates that the

introduction of these treatments can extend the lifespan of welded mesh by up to

50%, making it a preferred choice in aggressive industrial settings.

This combination of enhanced material properties and innovative production methods positions

welded mesh as a critical component in the future of construction, meeting the demands for

higher performance while contributing to sustainable building practices.

Smart Welded Mesh Solutions for Real-Time Monitoring in Construction

The emergence of smart welded mesh solutions is revolutionizing construction with real-time monitoring capabilities. As the construction industry increasingly integrates Internet of Things (IoT) technology, the market is expected to reach $61.7 billion by 2030. This rapid growth is largely attributed to innovations in building information modeling (BIM) and advancements in safety equipment, which are transforming traditional construction practices. Companies are collaborating to enhance operational efficiency and safety, leading to a more connected job site.

Recent partnerships illustrate this trend, such as those aimed at integrating real-time occupancy intelligence into federal facilities. By utilizing advanced mesh technology embedded with monitoring sensors, construction firms can gain valuable insights into site conditions, improving project management and worker safety. Furthermore, with the construction wearable technology market expanding, the integration of smart wearable devices is enhancing the ability to monitor worker activities and environmental conditions in real time. As these innovations continue to unfold, they promise to deliver significant benefits in efficiency and safety for industrial applications.

Sustainable Innovations in Welded Mesh Materials for Eco-Friendly Projects

In the realm of construction and industrial applications, sustainable innovations in welded mesh materials are paving the way for eco-friendly projects. These advancements focus on using recycled metals and alternative materials that minimize environmental impact while maintaining the strength and durability required for structural support. The shift to eco-friendly welded mesh not only reduces the carbon footprint of construction sites but also promotes a circular economy by reusing materials that would otherwise contribute to waste.

Moreover, the integration of biodegradable coatings and treatments in welded mesh production is revolutionizing its application in landscaping and outdoor structures. These innovations provide enhanced resistance to corrosion and weathering while ensuring that the materials decompose safely at the end of their lifecycle. By adopting such sustainable practices, the construction industry can significantly contribute to environmental conservation, aligning with global efforts to reduce pollution and promote sustainability in every phase of building development.

Advanced Structural Designs in Welded Mesh for Industrial Applications

The advancements in welded mesh technology are increasingly shaping the architecture and functionality of industrial applications. With the demand for stronger and more resilient structures, innovative designs are integrating advanced materials and manufacturing techniques to enhance performance. These new structural designs feature improved load-bearing capabilities and corrosion resistance, making them ideal for various industrial environments, from construction sites to manufacturing facilities.

Furthermore, the incorporation of smart technologies into welded mesh applications is revolutionizing safety and monitoring systems. Sensors embedded within the mesh can detect stress and strain, providing real-time data that helps prevent structural failures. This proactive approach not only enhances the longevity of structures but also significantly reduces maintenance costs. As industries continue to embrace these advanced designs, welded mesh will play a crucial role in the future of construction and infrastructure, paving the way for more efficient and durable building processes.

Top 2025 Welded Mesh Innovations for Construction and Industrial Applications

| Innovation | Material Type | Strength (MPa) | Application | Year Introduced |

|---|---|---|---|---|

| Eco-Friendly Welded Mesh | Recycled Steel | 450 | Sustainable Construction | 2025 |

| Corrosion-Resistant Mesh | Stainless Steel | 600 | Marine Structures | 2025 |

| High-Strength Welded Mesh | Carbon Steel | 700 | Heavy Machinery | 2025 |

| Lightweight Composite Mesh | Composite Materials | 350 | Aerospace | 2025 |

| Fire-Resistant Welded Mesh | Special Alloy | 800 | Industrial Furnaces | 2025 |

Automation and Efficiency Boosts in Welded Mesh Manufacturing Processes

The landscape of welded mesh manufacturing is undergoing a transformative shift as automation and efficiency take center stage. With the global welded mesh market projected to reach USD 15 billion by 2025, manufacturers are increasingly integrating advanced technologies into their production processes. According to a recent report from Smithers Pira, the adoption of automated welding systems is expected to enhance production speed by up to 50%, drastically reducing lead times and labor costs.

Furthermore, the implementation of Industry 4.0 principles is enabling manufacturers to leverage smart factories, where interconnected machines communicate and self-optimize for improved efficiency. This shift not only streamlines operations but also minimizes material waste—a critical concern given that the construction industry alone generates approximately 1.3 billion tons of waste annually. Reports indicate that with automated mesh manufacturing, waste can be reduced by as much as 20%, ensuring a more sustainable approach to construction and industrial applications. As the demand for welded mesh continues to rise, these innovations are crucial for staying competitive in a rapidly evolving market landscape.

Related Posts

-

The Essential Guide to Understanding the Benefits of Welded Mesh in Modern Construction

-

Exploring the Top 5 Advantages of Welded Wire: Data-Driven Insights for Construction and Agriculture

-

Future Trends in Best Cable Mesh Market Analysis by 2025 with Real World Examples

-

How to Choose the Right Fence Wire for Your Specific Needs and Projects

-

10 Best Wire Mesh Cable Tray Solutions for Efficient Cable Management

-

Understanding the Benefits of Cable Tray Systems for Modern Electrical Installations